Error de format de correu electrònic

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Custom Electronic Components: Tailored Solutions for Modern Applications

In the fast-paced world of technology, the demand for custom electronic components has skyrocketed. As industries evolve, so do their needs for specialized components that can meet unique specifications. This blog post explores the importance, benefits, and applications of custom electronic components, delving into the reasons why businesses are increasingly turning to these tailored solutions.

What Are Custom Electronic Components?

Custom electronic components are specially designed and manufactured parts that meet specific requirements set by the customer. Unlike off-the-shelf components, which are standardized and mass-produced, custom components are created to address unique challenges, ensuring optimal performance and compatibility with the intended application.

Why Choose Custom Electronic Components?

The choice of custom electronic components over standard ones is driven by several key factors:

Specific Requirements: Custom components are tailored to meet precise specifications, ensuring they perform optimally in their intended application.

Improved Performance: By designing components to exact needs, businesses can achieve better performance, reliability, and efficiency.

Competitive Advantage: Companies that utilize custom components can often offer superior products and services, setting them apart from competitors.

Benefits of Custom Electronic Components

The advantages of opting for custom electronic components are manifold. Below are some of the most significant benefits:

Enhanced Functionality

Custom components are designed to function seamlessly within a specific system, enhancing overall performance. Whether it's a unique sensor, a specialized microcontroller, or a bespoke power supply, these components can significantly improve the functionality of the end product.

Cost Efficiency

While the initial cost of designing and manufacturing custom components might be higher, the long-term benefits often outweigh the expenses. By reducing the need for additional adjustments or modifications, custom components can lead to significant cost savings over time.

Quality Assurance

Custom components are typically subject to rigorous testing and quality control processes. This ensures that they meet the highest standards of reliability and durability, reducing the risk of failure and the need for costly repairs or replacements.

Applications of Custom Electronic Components

Custom electronic components find applications across a wide range of industries. Here are some examples:

Automotive Industry

In the automotive sector, the electronic components are used to develop advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) technologies. These components are critical for enhancing safety, comfort, and energy efficiency.

Medical Devices

The medical field relies heavily on custom components for diagnostic equipment, patient monitoring systems, and therapeutic devices. Customization ensures that these devices meet stringent regulatory standards and perform accurately in critical applications.

Consumer Electronics

From smartphones to wearable devices, consumer electronics often incorporate custom components to deliver unique features and superior performance. Customization allows manufacturers to differentiate their products in a highly competitive market.

Industrial Automation

In industrial settings, the electronic components are used to build robust automation systems. These components enable precise control and monitoring of industrial processes, leading to increased productivity and reduced downtime.

The Process of Developing Custom Electronic Components

Creating custom electronic components involves several critical steps:

Requirement Analysis

The first step in the development process is a thorough analysis of the customer's requirements. This involves understanding the specific needs and challenges that the component must address.

Design and Prototyping

Once the requirements are clear, the design phase begins. Engineers create detailed designs and develop prototypes to test the component's functionality and performance.

Testing and Validation

Prototypes undergo rigorous testing to ensure they meet the desired specifications. This phase includes various tests, such as stress testing, environmental testing, and compatibility testing.

Production

After successful validation, the component moves into the production phase. Advanced manufacturing techniques are used to produce the component at scale while maintaining high quality.

Quality Control

Quality control is a crucial aspect of the production process. Each component undergoes stringent quality checks to ensure it meets the highest standards before it is delivered to the customer.

Choosing a Partner for Custom Electronic Components

Selecting the right partner for developing custom electronic components is critical. Here are some factors to consider:

Expertise and Experience

Look for a partner with extensive experience in designing and manufacturing custom components. Their expertise can make a significant difference in the quality and performance of the final product.

Technological Capabilities

Ensure that the partner has access to advanced technologies and tools required for developing custom components. This includes state-of-the-art design software, prototyping equipment, and testing facilities.

Quality Standards

Quality should be a top priority. Choose a partner who adheres to stringent quality standards and has a robust quality control process in place.

Cost-Effectiveness

While cost is an important consideration, it should not be the sole deciding factor. Evaluate the overall value offered by the partner, including their ability to meet deadlines, provide technical support, and deliver high-quality components.

Case Study: Successful Implementation of Custom Electronic Components

Let's take a look at a real-world example of how the electronic components can make a difference. A leading manufacturer of industrial automation systems needed a specialized sensor to improve the accuracy of their machinery. Off-the-shelf sensors were not meeting their requirements, leading to frequent breakdowns and costly repairs.

The Challenge

The existing sensors were not durable enough to withstand the harsh industrial environment, resulting in frequent failures. The manufacturer needed a custom solution that could offer better durability and accuracy.

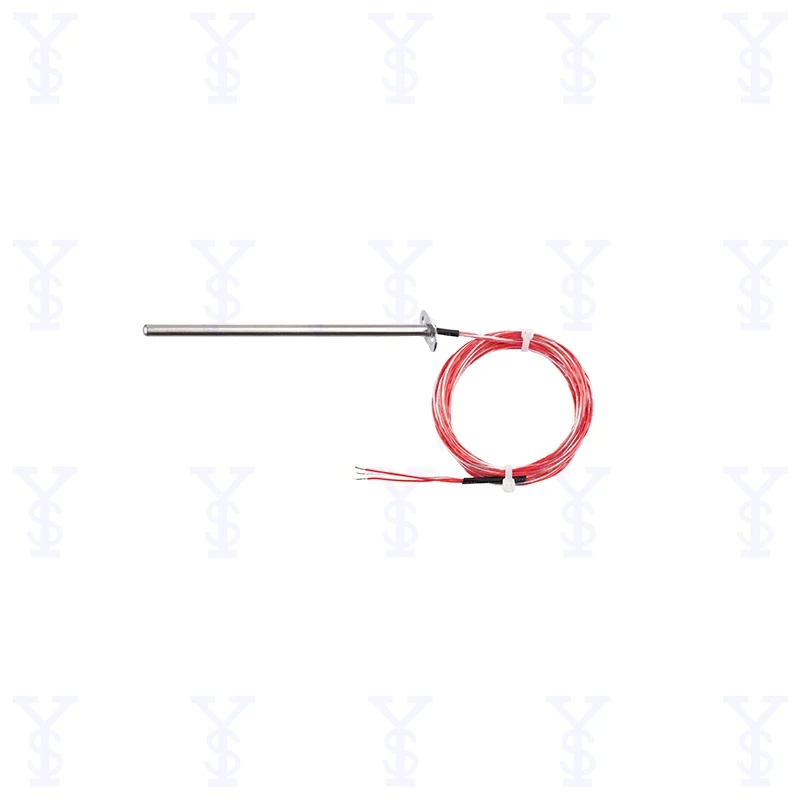

The Solution

After a detailed analysis, a custom sensor was designed and developed. The new sensor featured enhanced durability, higher accuracy, and better resistance to environmental factors. It was rigorously tested to ensure it met all the required specifications.

The Result

The implementation of the custom sensor led to a significant reduction in machine downtime and maintenance costs. The manufacturer reported improved productivity and efficiency, validating the investment in custom electronic components.

Future Trends in Custom Electronic Components

The future looks promising, with several trends shaping the industry:

Advanced Materials

The use of advanced materials, such as graphene and nanomaterials, is expected to revolutionize the development of custom components. These materials offer superior properties, such as higher conductivity and better thermal management.

Miniaturization

As devices become smaller and more compact, the demand for miniaturized custom components will increase. This trend is particularly evident in the consumer electronics and medical device industries.

Internet of Things (IoT)

The proliferation of IoT devices is driving the need for custom components that can support connectivity and data processing. Custom sensors, microcontrollers, and communication modules will play a crucial role in the growth of IoT.

Artificial Intelligence (AI)

AI is transforming the design and manufacturing of custom electronic components. AI-driven tools can optimize the design process, improve testing accuracy, and predict potential failures, leading to higher quality and reliability.

Conclusion

Custom electronic components are essential for meeting the unique needs of various industries. They offer enhanced functionality, improved performance, and better cost efficiency compared to standard components. As technology continues to evolve, the demand for these tailored solutions will only grow, driving innovation and excellence in electronic design and manufacturing.

By partnering with experienced and capable manufacturers, businesses can harness the full potential of the electronic components to gain a competitive edge and achieve their operational goals. Whether in automotive, medical, consumer electronics, or industrial automation, the benefits of custom components are undeniable, paving the way for a smarter and more efficient future.

In conclusion, while cheap electronic components in China might be suitable for some applications, the investment in the electronic components often proves to be more valuable in the long run. The ability to address specific needs, ensure high quality, and achieve superior performance makes custom components a strategic choice for forward-thinking companies.